When you look at the world around you, do you think that the things you work with could be better? You should. That's how progress happens, and progress is a good thing.

In the late 50's, some guy named Eugene Stoner and a host of talented engineers came up with a rifle, and that rifle changed the world. It has had its ups and downs, but has pushed through them to continue on as the US military's battle rifle, and holds that spot over half a century later.

I want you to take a minute to think about that. Look at the pens your parents used. Different from what you use today? Look at an old car. Any backup cameras or Bluetooth on those? Look at technology that didn't exist a year ago. Now look at America's favorite Black Rifle. There are a lot of things that don't need to be changed. And there's a lot that needs updating.

That is the maddening dichotomy of Stoner's design. On one hand you have an amazing array of upgrades, newer lightweight parts, barrels, parts and accessories that Stoner could never have dreamed of. On the other hand, there is the dogmatic adherence to what is commonly referred to as mil-spec. Now mil-spec is good, and people hold it up as the holy grail for a great reason. The reason is this: people who put out more rounds than you or I ever will have confirmed the specs and go to war with that package. Whatever can be said about the M4 in the sandbox, I have never heard of anyone saying their hammer broke or their trigger snapped off.

The problem lies in the fact that very few manufacturers have the technical data packages for what is mil-spec, because they supply these weapons to Uncle Sam. Everything else, and that means what's in YOUR (and my) gun is cloned off the end specs of that TDP. So, unless you have that in at the company that makes guns for the tip of the spear guys, you don't have true mil-spec in your gun. You just don't.

So where does this leave us? With a gun that runs off of parts that are clones of specs that are over 60 years old and manufacturers that are scared to make changes because the shooting community's disdain for anything not mil-spec. And that standard is practically invalid, since the parts claimed to be mil-spec really aren't. You can see that companies are starting to take that into account in their branding. Daniel Defense has Mil-Spec+, others have Mil-Standard, Enhanced Mil-Spec, and so on. As companies realize they can improve upon the mil-spec package without fear of reprisal, certain advances are coming to light, from titanium parts to side charging receivers. If you look at the piston AR, you'll see the exact same trend.

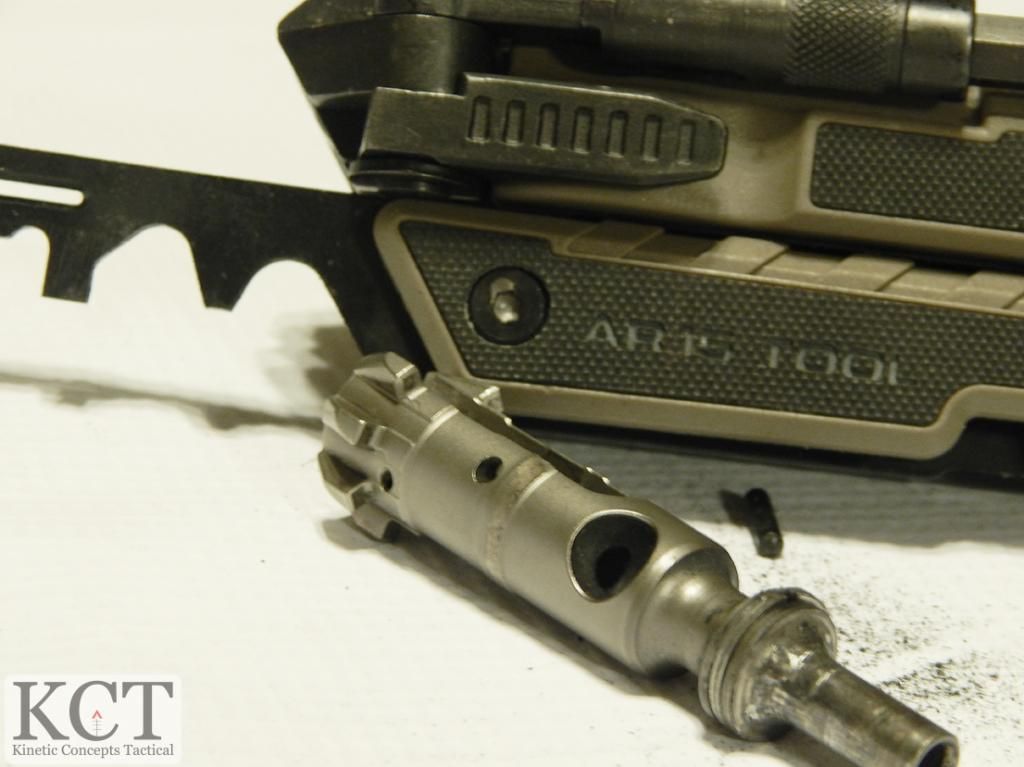

The newly re-organized Sharps Rifle Company has thrown their hat into the ring of the AR's evolution with their new Relia-Bolt. It is an optimized bolt for the 5.56 AR pattern rifles, which also works with the main offshoots of that caliber, the 300 AAC Blackout and the 25-45 Sharps.

Construction

SRC supplies their Relia-Bolt as a complete bolt assembly, ready to drop into your bolt carrier.

The bolt includes:

Bolt

Gas rings

Extractor assembly- extractor, extractor pin, extractor spring with black insert, o-ring

Ejector assembly- ejector, spring, and retaining pin

The bolt is Magnetic Particle Inspected, High Pressure Tested, and shot peened. It is also coated with NP3, which bonds Teflon particles to the material. When you handle the bolt, you can feel how slick it is due to this process.

The Relia-Bolt has extra material on the lugs around the extractor. This reduces the chance that the weakest lugs on the bolt (the lugs on either side of the extractor) will shear off.

The lugs on the bolt are beveled to aid in locking and unlocking with the lugs on the barrel extension. This lowers the frictional coefficient with the barrel extension, and reduces wear on the bolt and rifle. The bottom pair of lugs are left at the full length to pick up the rounds from the magazine.

SRC's enhanced bolt is well put together. All the pins and springs are tucked in like they should be, and the extractor is machined perfectly, with the "kitten teeth" at the corners like they should be. The bolt is compatible with aftermarket extractors like the BCM should you need to replace it.

Field Use

The Relia-Bolt has so far proven relentlessly reliable. It ejects spent casings with authority, and has no difficulty with brass or steel cased ammunition. So far my tests have been on my 5.56 carbine. I will be testing with 300BLK when I acquire the ammo to put it through its paces. I have been deliberately shooting .22 in a conversion kit before shooting .223/5.56 through the gun. I have also been using dirtier steel-cased ammo, which can be problematic for some guns. I figure that if there's a failure to be had, it will be running the rough stuff.

The following items are tests that have been performed with the Relia-Bolt, and include any notes and observations we made during use or inspection.

7/18/14

16" carbine (DI)

Carbine had 300 rounds of .22 fired through it with a CMMG conversion kit. 40 rounds of steel-cased .223 was fired through it. Gun is dirty, not cleaned after shooting. No cycling, extraction, feeding issues. The gun never failed to go into battery.

7/25/14

16" carbine (DI)

Carbine was fouled with 500 rounds of .22LR ammunition fired through CMMG conversion kit.

100 rounds of steel-cased .223 (Tula) fired, 50 rounds in a mag dump. Gun is filthy. No cycling, extracting, ejection, or feeding issues.

9/5/14

16" carbine (DI)

Carbine ran 120 rounds, mixed Silver Bear .223, Tula steel case .223, and Lake City brass 5.56. The rifle was sight-checked at 100 yards using 5-round groups using slow fire for accuracy. The gun was then put through short drills and plinking. No issues were noted. The BCG was replaced with a CMMG Bravo .22 conversion kit, and 125 rounds of mixed .22 was fired- CCI, Remington Golden Bullet, Blazer, and Fiocchi. The 5.56 BCG was replaced and the gun fired a further 60 rounds to clear the .22 residue from the gun. The gun was run in short drills of 10 rounds each. No malfunctions. The gun had not been cleaned to date.

Further testing will be conducted, and a second KCT shooter will be running the Relia-Bolt in his carbine for further independent testing.

The carbon on the bolt tail was predictably tougher than the rest of the bolt. A quick pass with the AR-15 Tool's carbon scraper took off the majority of the carbon on the bolt tail in seconds.

The ease of cleaning with the SRC bolt is truly impressive. Anyone who has spent time cleaning an AR knows that the bolt can be the most time consuming part of the job. Being able to wipe down the bolt and return it to functional tolerance is a great upside, especially for shooters who put a lot of rounds on their gun.

Final Thoughts

I have put thousands of rounds through various guns on mil-spec bolts. With the exception of a crappy R'Guns upper, they have all worked fine. Be that as it may, there's a lot of change on the horizon for your favorite black rifle. There are many companies offering special coatings and upgrades to the standard bolt, and most of them are pretty good. However, the redesign that SRC has slapped on the table makes so much sense you wonder why it wasn't done years ago.

After testing the Relia-Bolt, I won't be putting my standard bolts back in my gun.

You can find out more and pick one up for yourself here. For an intro price of $79.99, it's a hell of a steal for a great piece of kit.

Kinetic Concepts Tactical

No comments:

Post a Comment