Origins

The Hexmag 30-round magazine for the AR-15/M4 family of weapons is the flagship product of Hexmag, a Colorado-based weapon components company.

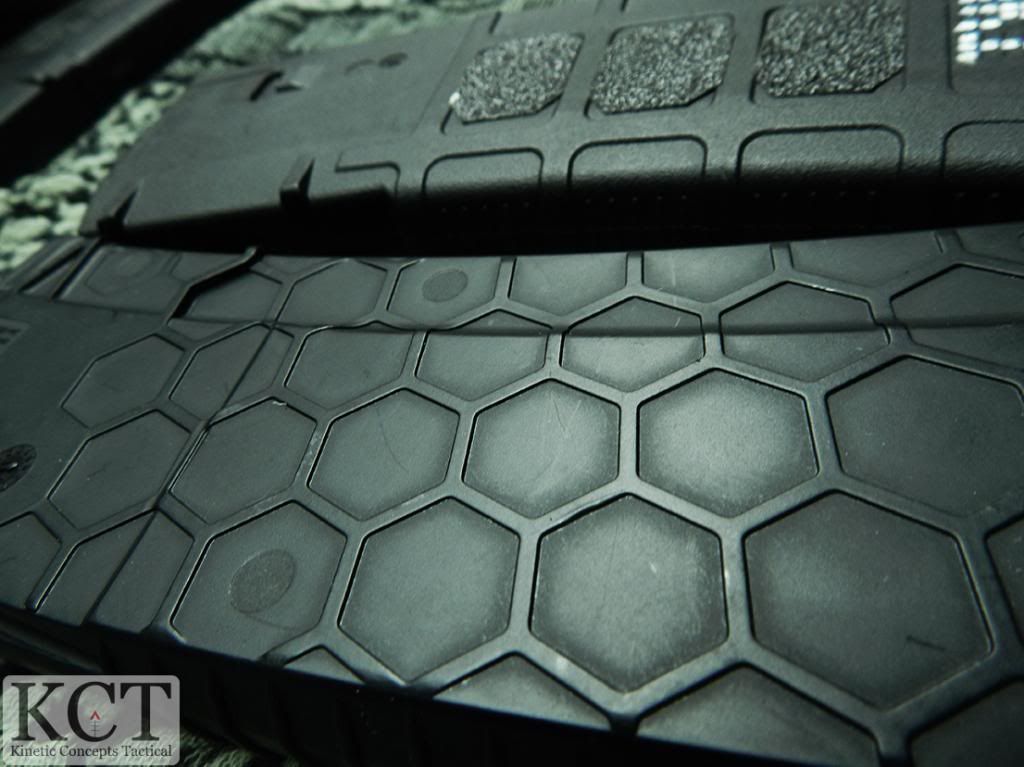

Not to be confused with a similar story, Hexmag has come out of the gates with a bold design that's as eye-catching as it is useful. The magazine body is textured in rigid, raised hexagons, hence the name. The follower and latchplate are made to be user-replaceable with a wide variety of factor supplied colors. This aids in easy magazine identification to determine ownership, and more importantly, ammunition type.

Before we dive into the details, let's look at how Hexmag came to be. The review samples I received came with a letter from Hexmag President Aaron Sheffter, who stated that Hexmag sourced their springs from the same company that provides them to Magpul. As Magpul moved its operations out of Colorado, there was a void in the manufacturing market. I was eager to see how Hexmag handled the politics and pressures of operating in such an anti-gun climate. To this end, I corresponded with Craig Sweeney, Hexmag's Marketing Director:

KCT: What was the design concept behind the mags? Was it born from 3-gun users?

Craig: The

inspiration for the magazine actually came out of a simple design

exercise by two of the founders. They have been lifelong firearms

enthusiasts and really just wanted to try it out. One of the two has a

pretty solid understanding of 3D CAD software, so that coupled with

their personal experiences with a multitude of AR mags got them going.

Ultimately, the first samples were 3D prints done at a very high-end

prototyping facility in Denver. The entire development process took a

little over a year.

The

inspiration for HexID was really just one of those things that comes

out of personal use. It's a simple alternative to paint pen marking magsKCT: Do you plan to release other capacities?

Craig: Yes, we are getting these first products off the ground and then we'll expand the product line to include other capacity magazines and additional parts - grips, forends, etc - and we'll likely expand into AK products as well.

KCT: Obviously

you're in Colorado, the state that Magpul famously pulled out of. You

source your springs from the same company. Did Hexmag come about to

fill the capacity in manufacturing as Magpul pulled out?

Craig: No, Hexmag is completely independent of Magpul. We have had talks with a few former Magpul employees, but currently there is no connection between the two companies. We use that spring manufacturer because we wanted to keep as much of our sourcing as possible and they are the best option. With the exception of our plastics and our packaging printing coming from suppliers in the Midwest, all of our sourcing and production is in Colorado.

KCT: You're making some (very nice looking) rifle grips. Do you plan on making other weapons components as well?

Craig: Yes,

the grips are likely the next product release. Specific to grips we're

doing R&D for a product that does not exist in the market. Too early

show any concept drawings, but when we're ready I'll be sure to let you

know.

KCT: Any plans for a clear or windowed Hexmag?

Range Time

I took four Hexmags out to MDFI's Foundation Carbine and Carbine Basics courses on 4/26-27 2014 with a fellow KCT shooter, Eric. We wanted to put these through their paces and see what we thought about them. It was a nice change to leave the PMAGs, Lancers, and GI mags in the ammo box, and try out something different.

We color coded our magazines, orange for Eric and green for me. We loaded them up with Tula steel case ammo and Wolf brass case, and hit the range.

Over the course of the classes, we had about 800 rounds pass through the magazines. Not once did we have a single hiccup with the magazines. We perfomed several intentional and unintentional drop tests on concrete and the grass of the range. The most the mags did is cough out a single round, which is pretty normal in these tests. No cracks, dents or damage other than a minor scuff or two was reported. The mags were stepped on, dropped, kicked, and filled with sand and debris, and kept feeding reliably.

The mags got a lot of attention from our fellow shooters and instructors. Their distinctive look and color-coding system really seemed to click with the staff and shooters, many of which remarked that they liked the brightly colored followers for assessing an empty weapon through the ejection port, especially when running reload drills. The ability to easily mark your rounds was a big hit as well.

I'd like to point out that if anything is going to fail, its not going to be at the indoor range, or while shooting with your buddies. It's going to be while someone is yelling at you to get your gun back into the fight while you're clearing a jam, and a lot of guns went down in this class. Also, quite a few mags crapped out, mostly GI mags. It was nice to be shooting with reliable magazines, especially when the trash bins at the loading areas were catching junk magazines at a fairly regular pace. So far, these Hexmags have been top notch, and being polymer, are less susceptible to the feed lip creep of their metal counterparts.

Craig: Not currently. Again, demand would probably dictate whether that happens.

KCT: We love the packaging by the way.

Craig: Thanks.

We really wanted to create something that stood out in a retail setting

from the military surplus feel that's pretty common in this market. We

looked at several other markets - tools, sporting goods, men's skincare

products, etc. - in coming up with our branding.

Range Time

I took four Hexmags out to MDFI's Foundation Carbine and Carbine Basics courses on 4/26-27 2014 with a fellow KCT shooter, Eric. We wanted to put these through their paces and see what we thought about them. It was a nice change to leave the PMAGs, Lancers, and GI mags in the ammo box, and try out something different.

We color coded our magazines, orange for Eric and green for me. We loaded them up with Tula steel case ammo and Wolf brass case, and hit the range.

Over the course of the classes, we had about 800 rounds pass through the magazines. Not once did we have a single hiccup with the magazines. We perfomed several intentional and unintentional drop tests on concrete and the grass of the range. The most the mags did is cough out a single round, which is pretty normal in these tests. No cracks, dents or damage other than a minor scuff or two was reported. The mags were stepped on, dropped, kicked, and filled with sand and debris, and kept feeding reliably.

The mags got a lot of attention from our fellow shooters and instructors. Their distinctive look and color-coding system really seemed to click with the staff and shooters, many of which remarked that they liked the brightly colored followers for assessing an empty weapon through the ejection port, especially when running reload drills. The ability to easily mark your rounds was a big hit as well.

|

| L-R: Hexmag, H&K, GI, M3, MOE |

I'd like to point out that if anything is going to fail, its not going to be at the indoor range, or while shooting with your buddies. It's going to be while someone is yelling at you to get your gun back into the fight while you're clearing a jam, and a lot of guns went down in this class. Also, quite a few mags crapped out, mostly GI mags. It was nice to be shooting with reliable magazines, especially when the trash bins at the loading areas were catching junk magazines at a fairly regular pace. So far, these Hexmags have been top notch, and being polymer, are less susceptible to the feed lip creep of their metal counterparts.

Construction

The Hexmag is a polymer design incorporating a captured follower, which is easy to change out for one of the other colors Hexmag offers. The spring is a chrome silicon wire which is produced by the same company that makes them for Magpul.. The colored latch plate is easy to depress with a finger, and once depressed it allows the floor plate to slide off the magazine body. The user can then swap out the latch plate for a different color, or perform any other maintenance.

The latch plate deserves special attention. It is held to the floor plate by spring tension, and locks into a hex shaped hole in the bottom of the floor plate. This makes the magazine incredibly easy to unload, even with a full 30 rounds. The user simply presses in the latch plate with their finger, spare round, or small tool, and then slides the floor plate off, making sure to capture the spring. The rounds then slide neatly out of the magazine through the bottom. The spring and follower are both captured to the spring, keeping them from flying across the room when you swap out the colors.

When we first got these magazines in for review, we wondered if it would be possible to accidentally engage the latch plate if the rifle was rested on the ground on top of a rock, shell casing or other piece of debris. This would be a very bad thing, as it could cause the floor plate to slip loose and dump the remaining rounds into the dirt.

Both Eric and I spent a lot of time in the dirt this weekend, amidst spent brass, live rounds and rocks. Not once did we encounter this issue. I'd like to point out that the PMAG uses a similar system with no issues as well.

The Hexmag noticeably does not have an exaggerated over insertion stop like the new M3 PMAG. These magazines were smashed repeatedly into both open and closed bolts with no issues.

Although the colored identifier tabs and followers have captured much of the attention, the rest of the Hexmag is equally amazing. The entire body is textured with Hexmag's signature polygonal texture. The front and rear of the magazine is also textured to provide the operator a sure grip in rapid magazine changes. During our range testing, the Hexmags had positive grip even in sweaty or gloved hands, much more so than GI or older PMAGs.

One thing that really sold me on the design was the slim body of the magazine. Using the rigid polygon texture of the body, Hexmag's engineers were able to make the design much slimmer than other magazines on the market. Like many polymer magazines, Hexmag uses small sections of the upper body to reduce wobble in the magwell, in this case a hexagon and a triangle are the shapes used to provide the proper fit, which looks great and keeps the magazine looking cohesive and unified.

Along those lines, Hexmag has designed some interesting packaging, which makes the magazines stand out on retail shelves. Hexmags are visually striking in or out of the gun, and are pretty easy to spot amidst piles of other mags.

Check out Hexmag.com for more info or to order.

As always, thanks for reading. Stay safe and shoot straight.

Kinetic Concepts Tactical

The Hexmag is a polymer design incorporating a captured follower, which is easy to change out for one of the other colors Hexmag offers. The spring is a chrome silicon wire which is produced by the same company that makes them for Magpul.. The colored latch plate is easy to depress with a finger, and once depressed it allows the floor plate to slide off the magazine body. The user can then swap out the latch plate for a different color, or perform any other maintenance.

The latch plate deserves special attention. It is held to the floor plate by spring tension, and locks into a hex shaped hole in the bottom of the floor plate. This makes the magazine incredibly easy to unload, even with a full 30 rounds. The user simply presses in the latch plate with their finger, spare round, or small tool, and then slides the floor plate off, making sure to capture the spring. The rounds then slide neatly out of the magazine through the bottom. The spring and follower are both captured to the spring, keeping them from flying across the room when you swap out the colors.

When we first got these magazines in for review, we wondered if it would be possible to accidentally engage the latch plate if the rifle was rested on the ground on top of a rock, shell casing or other piece of debris. This would be a very bad thing, as it could cause the floor plate to slip loose and dump the remaining rounds into the dirt.

Both Eric and I spent a lot of time in the dirt this weekend, amidst spent brass, live rounds and rocks. Not once did we encounter this issue. I'd like to point out that the PMAG uses a similar system with no issues as well.

The Hexmag noticeably does not have an exaggerated over insertion stop like the new M3 PMAG. These magazines were smashed repeatedly into both open and closed bolts with no issues.

Although the colored identifier tabs and followers have captured much of the attention, the rest of the Hexmag is equally amazing. The entire body is textured with Hexmag's signature polygonal texture. The front and rear of the magazine is also textured to provide the operator a sure grip in rapid magazine changes. During our range testing, the Hexmags had positive grip even in sweaty or gloved hands, much more so than GI or older PMAGs.

One thing that really sold me on the design was the slim body of the magazine. Using the rigid polygon texture of the body, Hexmag's engineers were able to make the design much slimmer than other magazines on the market. Like many polymer magazines, Hexmag uses small sections of the upper body to reduce wobble in the magwell, in this case a hexagon and a triangle are the shapes used to provide the proper fit, which looks great and keeps the magazine looking cohesive and unified.

Along those lines, Hexmag has designed some interesting packaging, which makes the magazines stand out on retail shelves. Hexmags are visually striking in or out of the gun, and are pretty easy to spot amidst piles of other mags.

Check out Hexmag.com for more info or to order.

As always, thanks for reading. Stay safe and shoot straight.

Kinetic Concepts Tactical

I recently bought 3 of these mags, and I couldn't be happier. I can't wait to see what products this company releases in the future.

ReplyDelete