History

Since its introduction in late 1959, the M16/AR-15 family of rifles and carbines has gone through more modifications, upgrades, and redesigns than any other firearm in history.

Much of this stems from Eugene Stoner's modular design, which allows the end user to replace barrels, handguards, stocks and more with relatively little effort. The modern AR-15 pattern rifle can be found in almost any caliber and configuration, from .22LR to .50BMG.

Ounces and Pounds

The core design of the AR is to remain a lightweight, hard hitting rifle. As manufacturing technologies advance, Stoner's venerable design is upgraded along with them. Barrels can be fluted, bolt carriers can be redesigned for lighter weight, new polymers allow for rugged furniture with substantial weight savings over the original design.

One thing very few designers have looked at is weight savings in the standard parts kit of an AR.

Changing the Standard

V7 Weapons Systems out of Grant's Pass, Oregon, is looking to change that. If the location sounds familiar, it should. V7 head honcho Joel Allen was the lead tech at Noveske before striking out on his own with V7.

V7 has started off by redesigning some of the core standard components of the AR carbine system, the castle nut and the lock plate.

Why would a new company with such an established pedigree in their past endeavors pick such mundane items to be a part of their flagship releases? Because they can make them lighter. And stronger. V7's website states that their parts offer a 60% or greater weight savings in these core components.

As the industry trend heads to lighter-weight designs, such as the Keymod system and the Magpul MOE line of parts, it's time the rest of the AR catches up.

Castle Nut

The V7 castle nut is unique in the fact that it is Mil-Spec type 3 hard anodized. This means that it is not the traditional color of bare metal, but is black instead. The nut is coated inside and out, so the threads are also anodized against wear.

On the "inside" of the nut (the side facing the rifle), it is marked with the V7 logo and the company's website. It has three separate indentations to allow the installer to properly stake the nut.

QD End Plate

Like the castle nut, the end plate is finished in a hard anodized coat with the company's logo and website on the inside and their stylized V7 logo on the outside.

The end plate features an integrated QD swivel socket which is flush with the exterior of the plate. Unlike many QD end plate designs, there is no protruding lip for the QD socket. This keeps the plate low-profile, and reduces the chance of gear or the sling snagging on it, as well as creating a cleaner-looking part. The socket allows 360-degree rotation of the swivel, however the castle nut limits the rotation somewhat.

The Benefit

Ounces equal pounds, and pounds equal pain. The old axiom is more true now than ever before. Everything you add to your rifle adds a bit of weight, and even the smallest piece of gear can end up tipping the scales as you pile on more and more accessories.

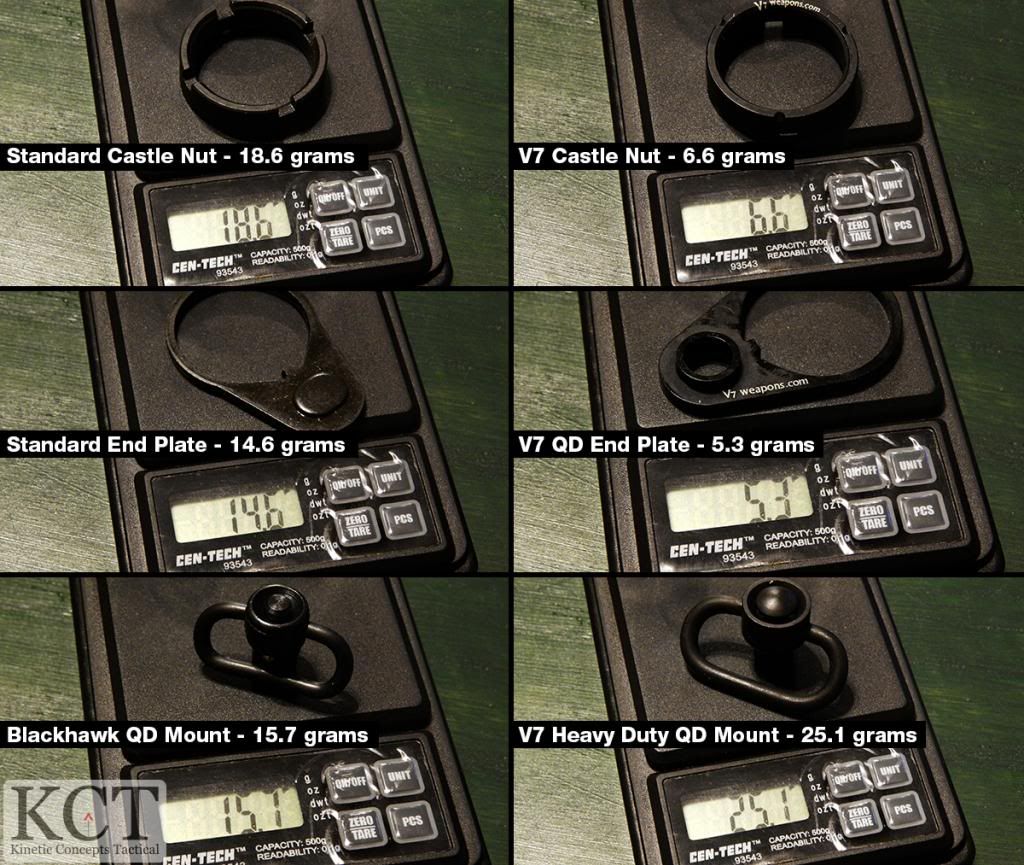

When you look at these parts, the claim of 60% or more weight reduction seems a bit hazy. Do you know what a mil-spec castle nut weighs? The end result that we found was this:

Standard Mil-spec castle nut and end plate: 33.2 grams

V7 castle nut, end plate and V7 Heavy-Duty QD sling swivel: 37 grams.

So the big savings for shooters is the fact that you can add a hard-use sling swivel for 4.2 grams. That is impressive.

You can see V7's entire line of components here.

No comments:

Post a Comment